ARDUINO STEPPER MOTOR STEP DIRECTION DRIVERS

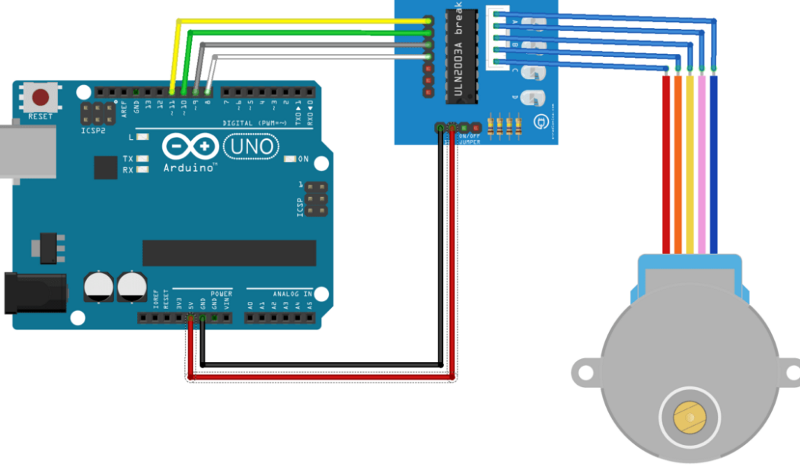

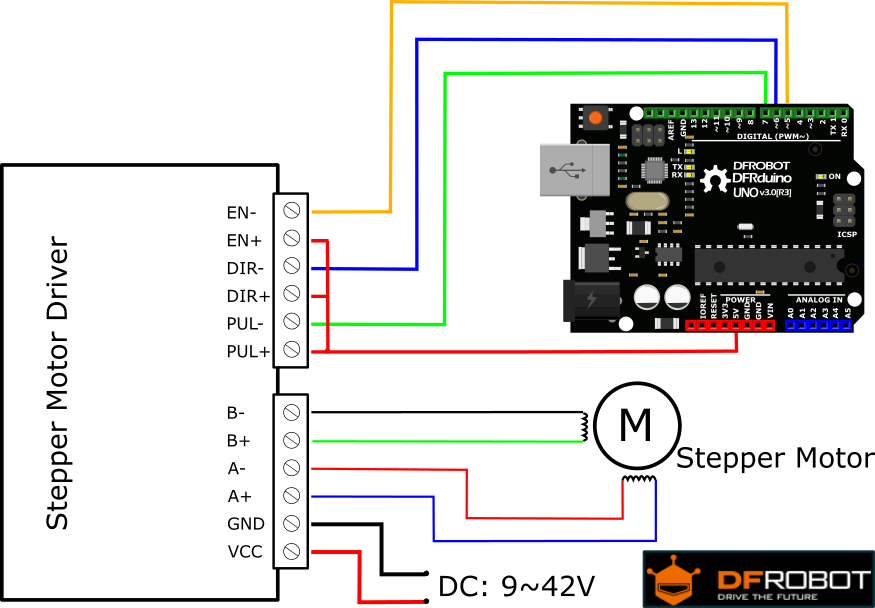

The price to pay is smaller torque, but extra precision is often more important than torque.Īlmost all stepper motor drivers use a “standard” protocol for controlling the motors. For example, with 1:8 microstepping, 100 steps-per-revolution motor has now 800 steps and each step is only 0,45 degrees. They can divide one step into smaller steps by precisely controlling magnetic fields. More than that, modern stepstick can do something called “microstepping”. You connect stepper coils, voltage, control signal and done! The driver will take care of how and when to energize each coil. They are all-in-one stepper motor controllers. The most popular are TCM2209, DRV8825, or A4988. To use steppers, you need a driver called a stepstick. Motor with 200 steps per revolution will move 1.8 degrees per step and so on. For example, a motor with 100 steps per resolution, will always move 3.6 degrees per one full step.

If you want it to move another “step”, you have to energize the coils in a different way. The main difference between a stepper motor and any other electric motor is that the stepper, when electricity moves through its coils, will rotate the shaft only by a defined angle, one step. This is why, we use steppers in cars, robots, all kinds of automation, 3D printers, CNC machines. You want something to more and move precisely how much wanted it to move? You use a stepper motor.

Stepper motors are the workhorse of modern automation and mechatronics.

0 kommentar(er)

0 kommentar(er)